Add to Cart

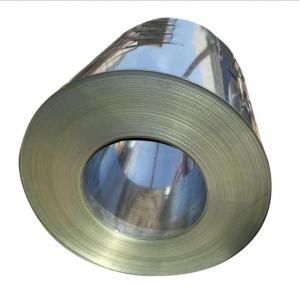

Cold rolled galvanized steel roll 0.8*16 mm 19 mm 32 mm Low Carbon PPGI HDG GI SECC DX51 ZINC coated

Galvanized Steel Coil Introduction

Cold rolled galvanized coil is a kind of galvanized steel sheet. Steel sheets and coils are classified into hot-rolled and cold-rolled according to rolling. Cold-rolled sheet is flat, rectangular, and can be directly rolled.

GI Coils Parameters

| Product Name | Galvanized Steel Coil |

| Thickness | 0.12-4.0mm |

| Width | 600-1250mm |

| Coil Weight | usually 3-4.5tons, max. 10 tons. |

| Zinc Coating | Z80-180 g/m2 |

| Coil Inner Diameter | 450/610mm |

| Steel Grade | DX51D,DX52D,DX53D,DX54D,DX55D |

| Surface | regular/mini/big/zero spangle |

| Packaging | Standard Export Packing |

| Delivery Time | 7-14 days after receipt of 30% deposit |

| Payment Terms | 30% T/T in advance, balance 70% T/T before x-factotry |

Cold rolling is a steel coil that is further thinned to a target thickness at room temperature. Compared with hot-rolled steel sheet, cold-rolled steel coil has more accurate thickness, smooth and beautiful surface, and also has various superior mechanical properties, especially in terms of processability. Because cold-rolled raw coils are relatively brittle and hard, and are not suitable for processing, cold-rolled steel coils are usually required to be annealed, pickled and surface smoothed before being delivered to customers.

The benefits of galvanizing:

1. Coated galvanized coils are very popular in adapting to various environments and have a long anti-corrosion period, but the anti-corrosion period is different in different environments.

2. The processing cost is low, and the anti-rust cost of galvanized coil is lower than other paint coatings.

3. Durable and durable. In suburban environments, a standard galvanized sheet rust coating can last for over 50 years without maintenance. In urban or offshore areas, the standard galvanized anti-rust layer can be maintained for 20 years without repair.

4. Good reliability, the metallurgical bond between the galvanized layer and the steel is part of the rigid surface, so the durability of the coating is more reliable.

5. The toughness of the coating is strong. The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

6. Overall protection, every part of the plated part can be plated with zinc, and it can be fully protected even in depressions, sharp corners and hidden places.

7. Save time and effort, the galvanizing process is faster than other coating construction methods, which can avoid the time of painting on the construction site after installation.